|

PinkMonkey Online Study Guide-Biology

10.2 Manufacture of Alcohol

A primary industrial alcohol is ethanol, or ethyl alcohol

(C2H5OH). Alcoholic fermentation is one of the oldest, best known and

most important of industrial fermentations. In this process, ethyl alcohol

is produced from carbohydrate materials (such as sugars) by yeasts. The

process is extracellular. The overall biochemical change accomplished

by the yeast is represented by the following equation.

This ability of the yeasts to convert sugars to alcohol and other end products of value has been exploited a great deal by brewers, bakers, distillers, wine makers, chemical manufacturers, vinegar manufacturers, etc.

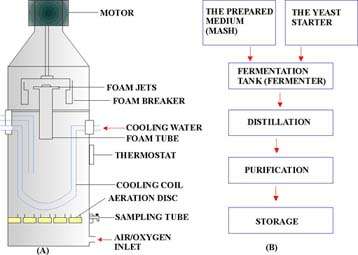

Figure 10.1(A) A Tubular Tower Fermenter

(B) Flow Chart of alcoholic fermentation

Manufacture of ethyl alcohol (Fig. 10.1)

Raw materials used : Molasses are one of the commonest raw materials used in the manufacture of alcohol. This is because they are cheap and readily available in large quantities. Micro-organism used : Selected strains of the yeast Saccharomyces cerevisiae are commonly employed for fermentation. This is because (a) they grow vigorously, (b) they have high tolerance for alcohol and (c) they have a high capacity for producing a large yield of alcohol.

Steps involved in the process

It is a large scale biotechnological process requiring

large scale tubular tower fermenters (bio-reacters) (Fig. 10.1A) and involves

the following steps.

Preparation of the medium : Water is added to the molasses to bring down the sugar concentration to the desired level (usually 30 to 40 percent). A measured quantity of acid is then added so as to adjust the pH on the acidic side. Addition of yeast : After adjusting the desired temperature, a yeast ‘starter’ is allowed to be mixed thoroughly with the molasses ‘mash’ in the fermentation tank.

|